Monday, December 16, 2024

Folding carton are an essential component of modern product packaging. Whether you’re buying cosmetics, food, or electronics, chances are you’ve encountered folding cartons in various packaging styles. These cartons are versatile, eco-friendly, and cost-effective packaging solutions, catering to diverse industries.

This article looks at the interesting world of folding cartons. It explores their many styles, materials, and manufacturing processes.

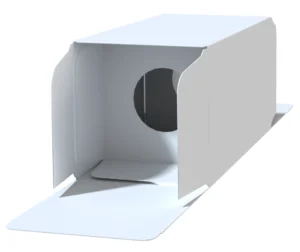

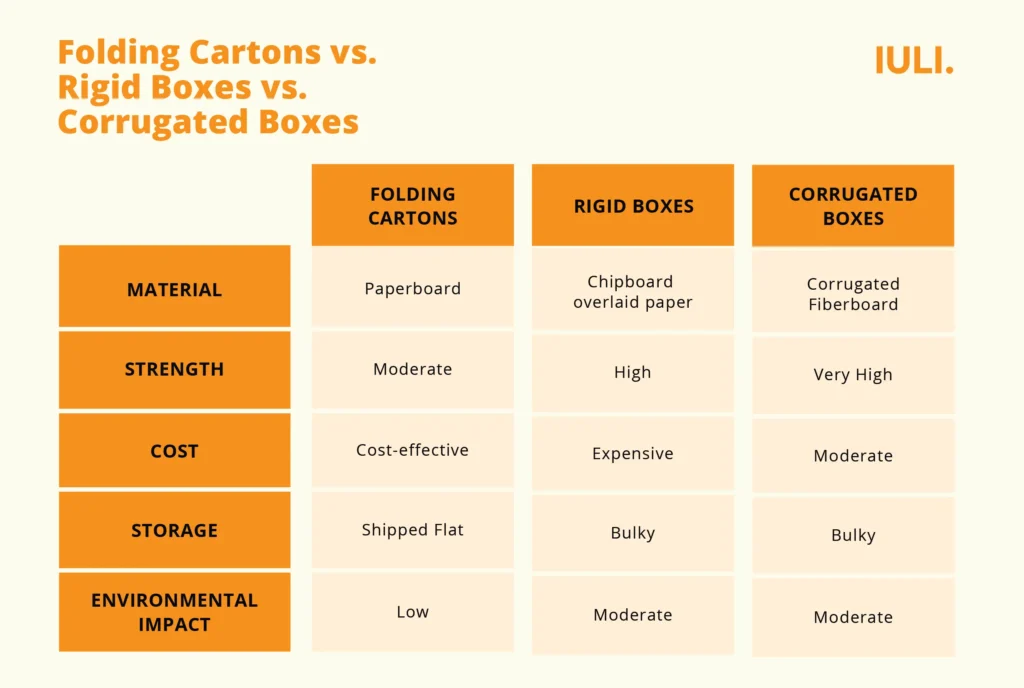

Folding cartons, also known by the abbreviation “F/C”, are lightweight boxes designed for efficient and durable product packaging. Shipping them flat optimizes space in the supply chain, reduces storage costs, and minimizes environmental impact. Folding cartons are easy to assemble, unlike rigid boxes. This makes them a cost-effective choice for businesses.

For industries aiming to balance functionality with aesthetics, folding cartons are the go-to choice.

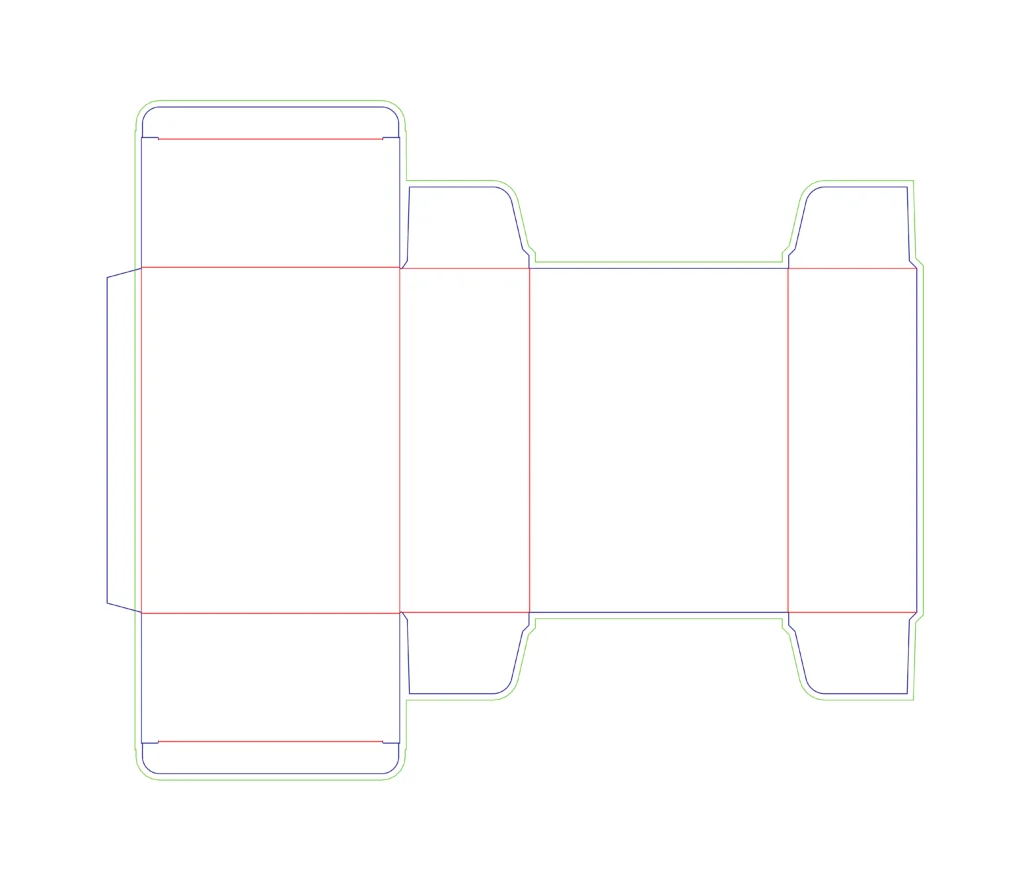

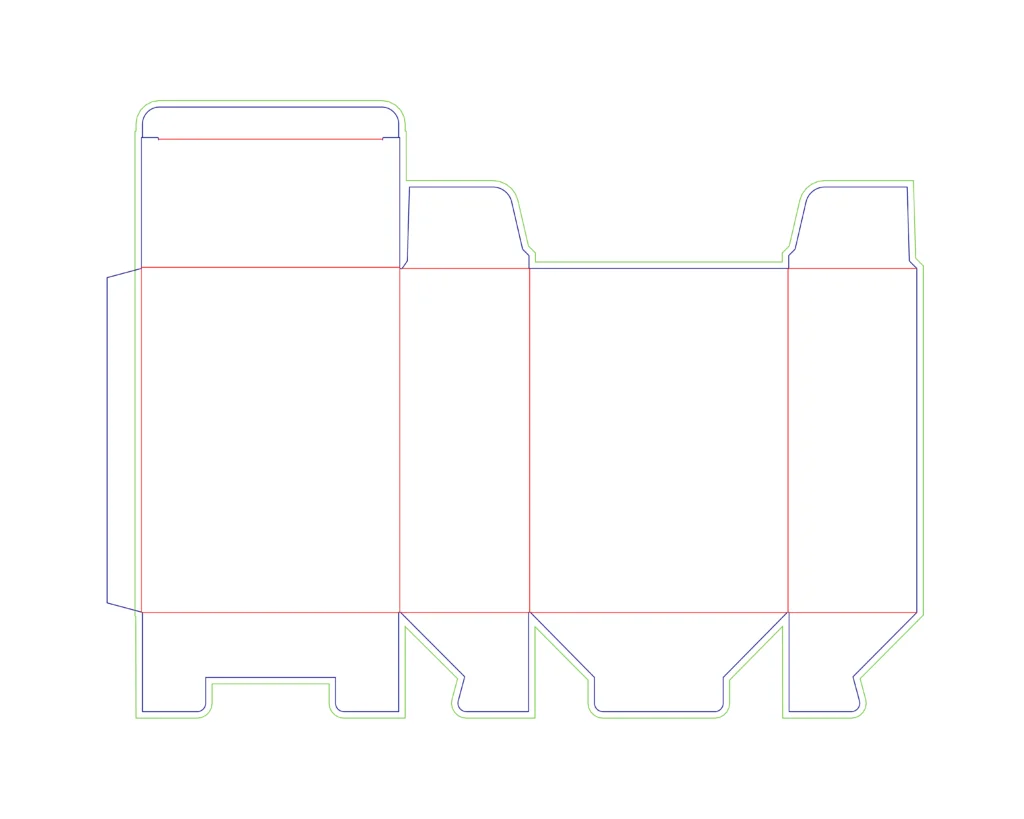

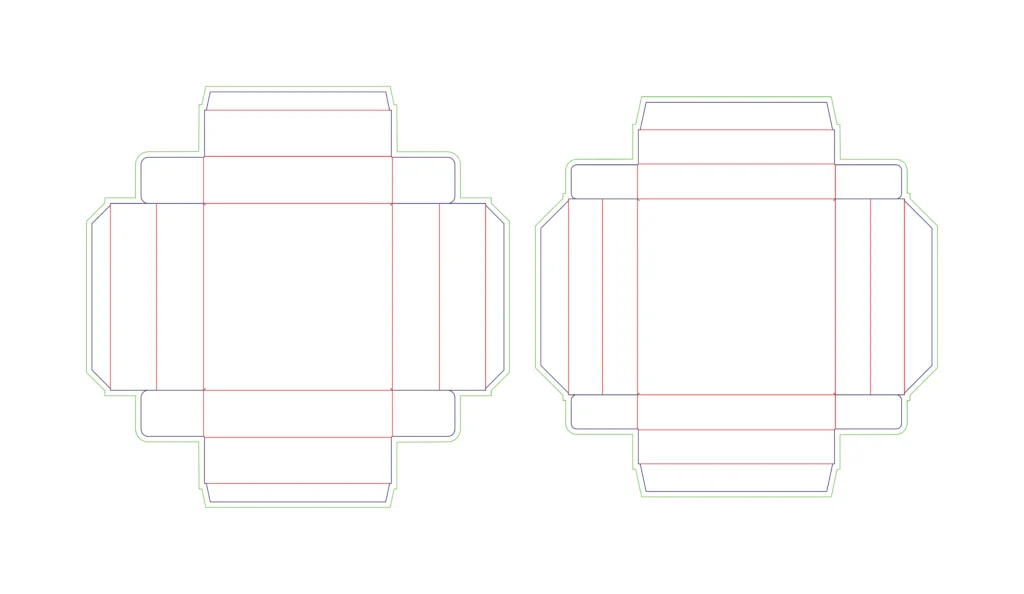

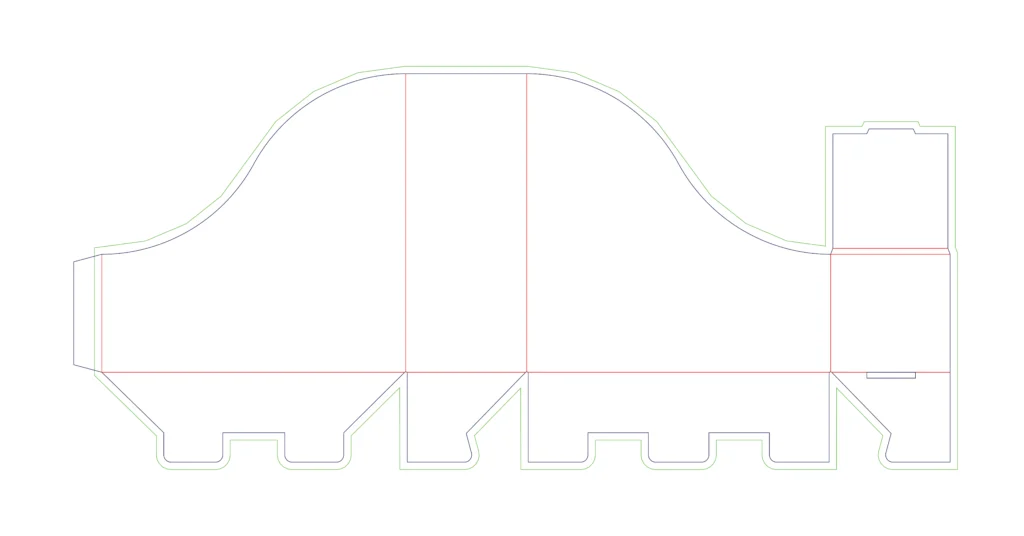

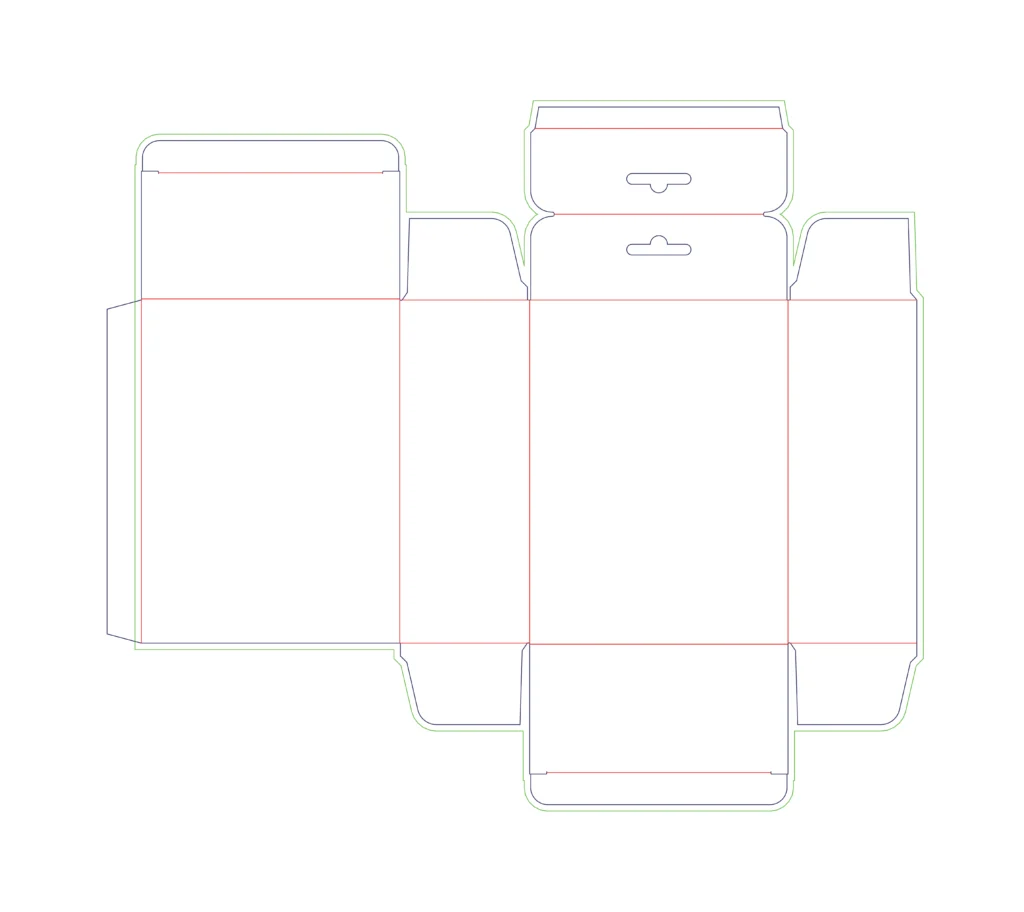

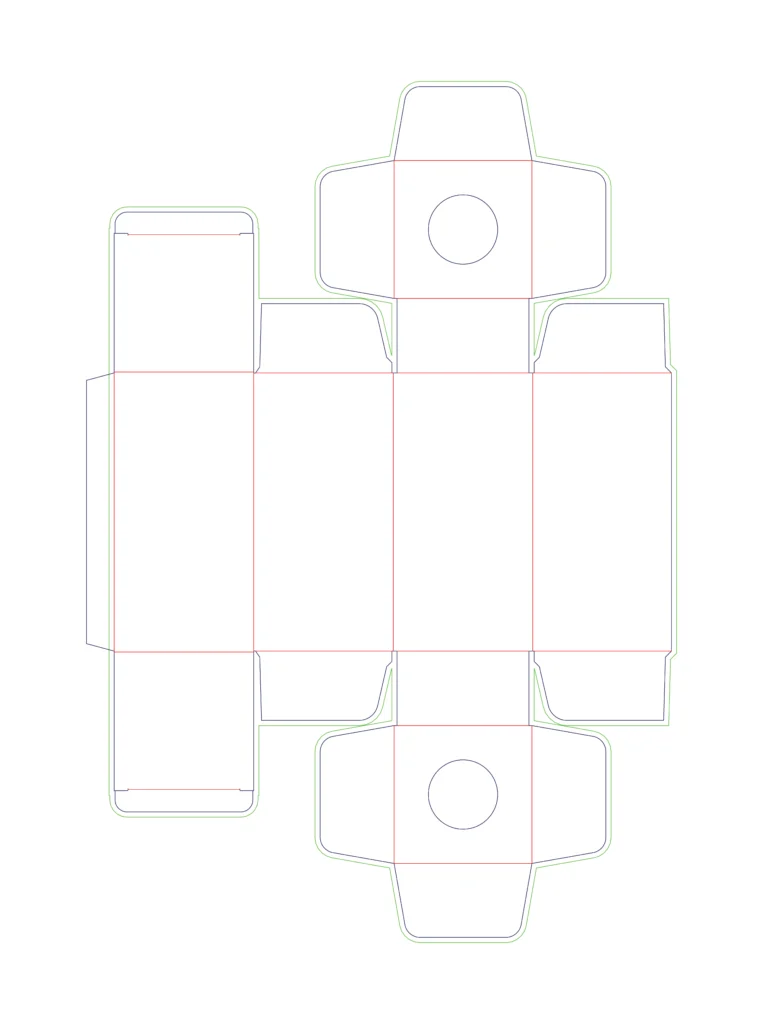

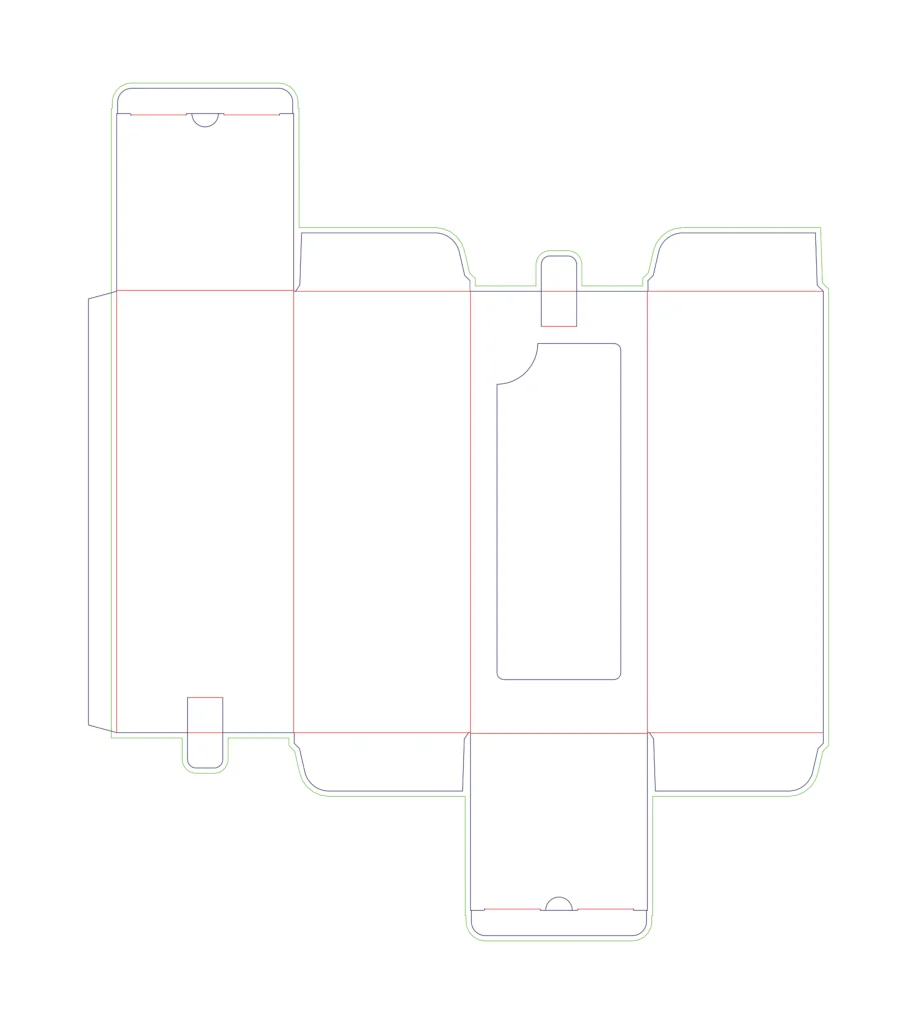

The world of folding cartons encompasses a wide range of designs, each tailored to different needs. Below are some of the most popular folding carton styles:

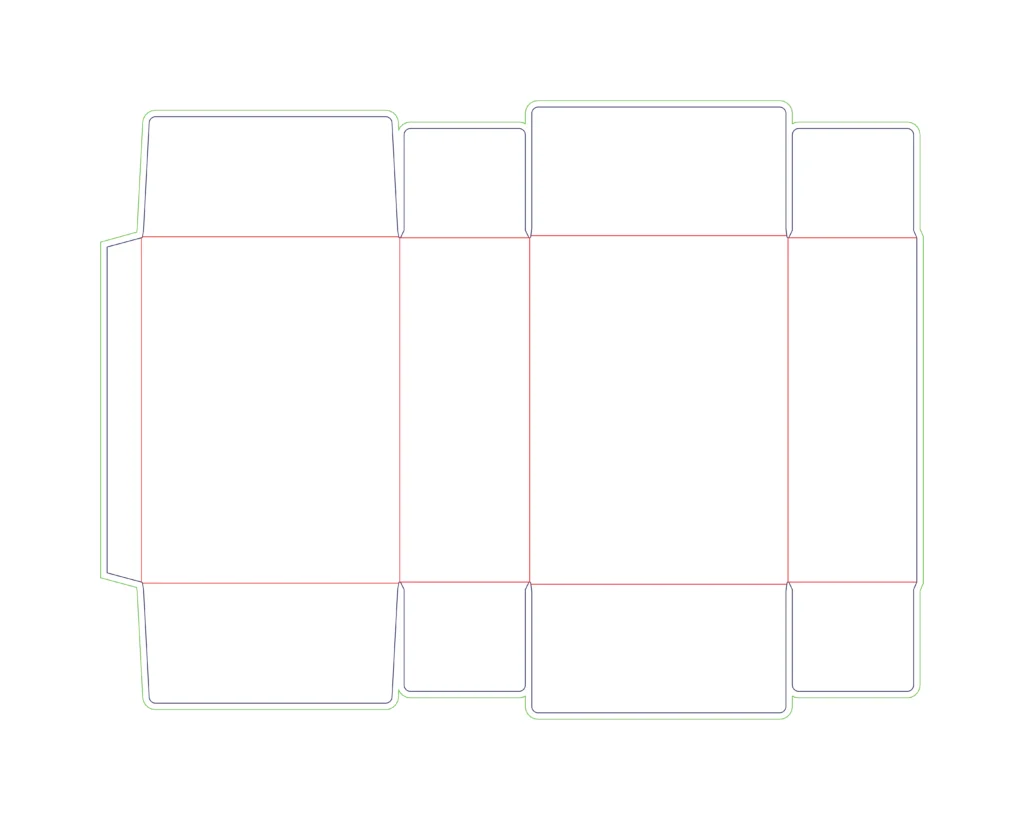

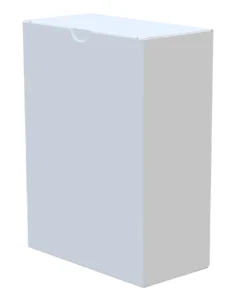

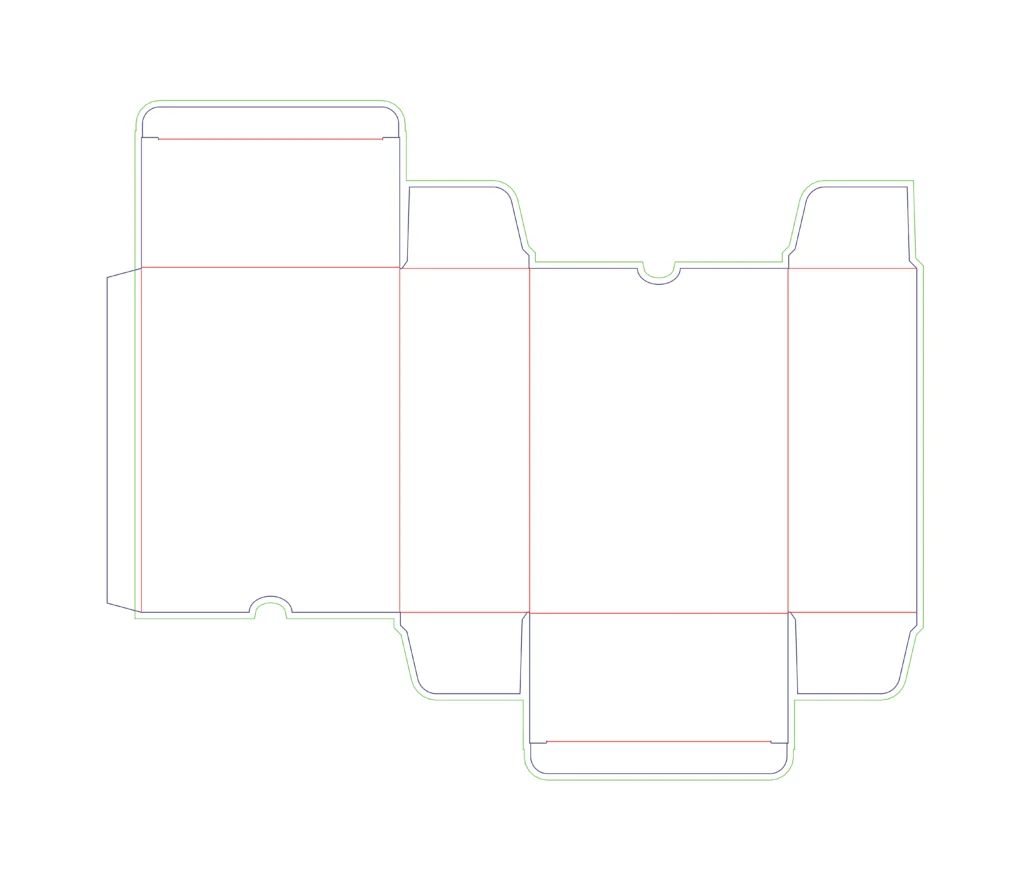

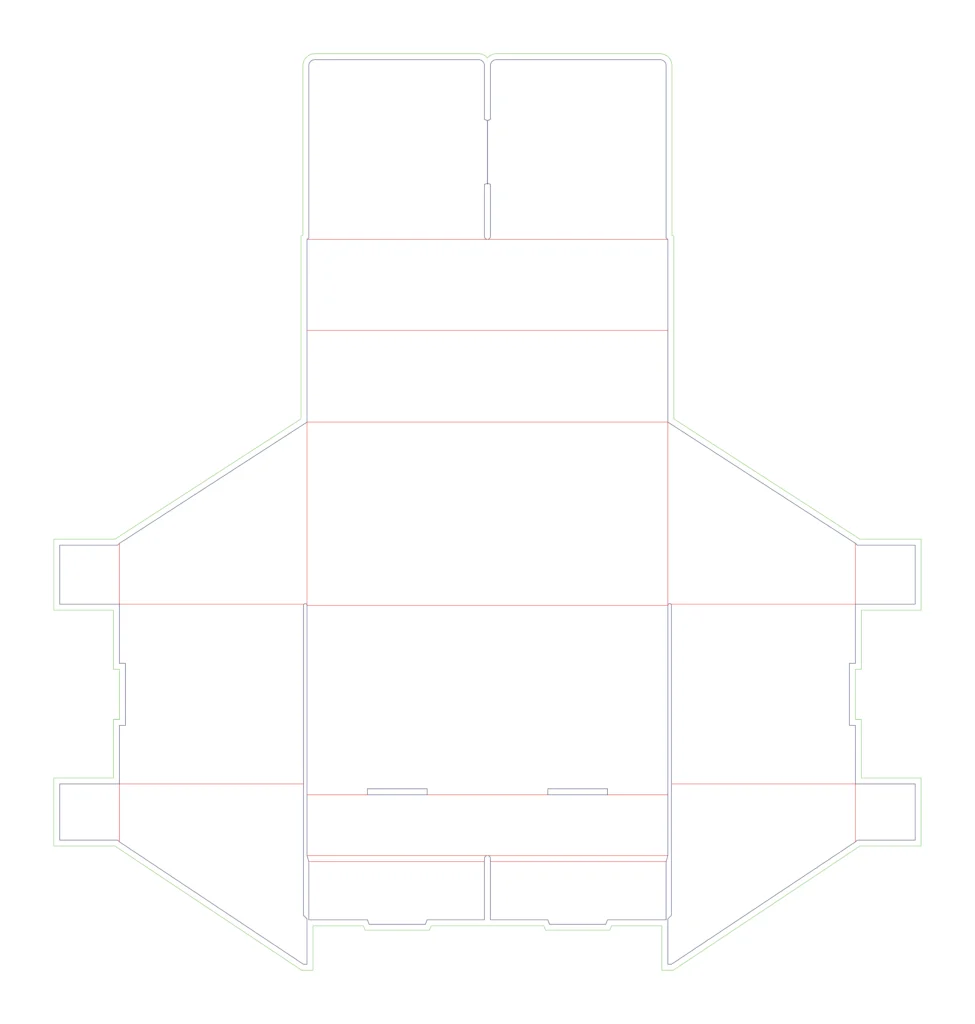

Features a seamless top and bottom closure with flaps that tuck in the same direction. Preferred for cosmetics, health products, and electronics.

Features a type of fold where the top and bottom flaps tuck in opposite directions for enhanced strength. Ideal for pharmaceuticals and lightweight items.

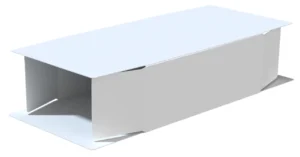

Offers extra durability and quick assembly with pre-glued bases. Often used for heavier products like glass jars, candles, and beverages.

Designed for easy assembly while providing excellent support. Popular for retail items that require efficient packing.

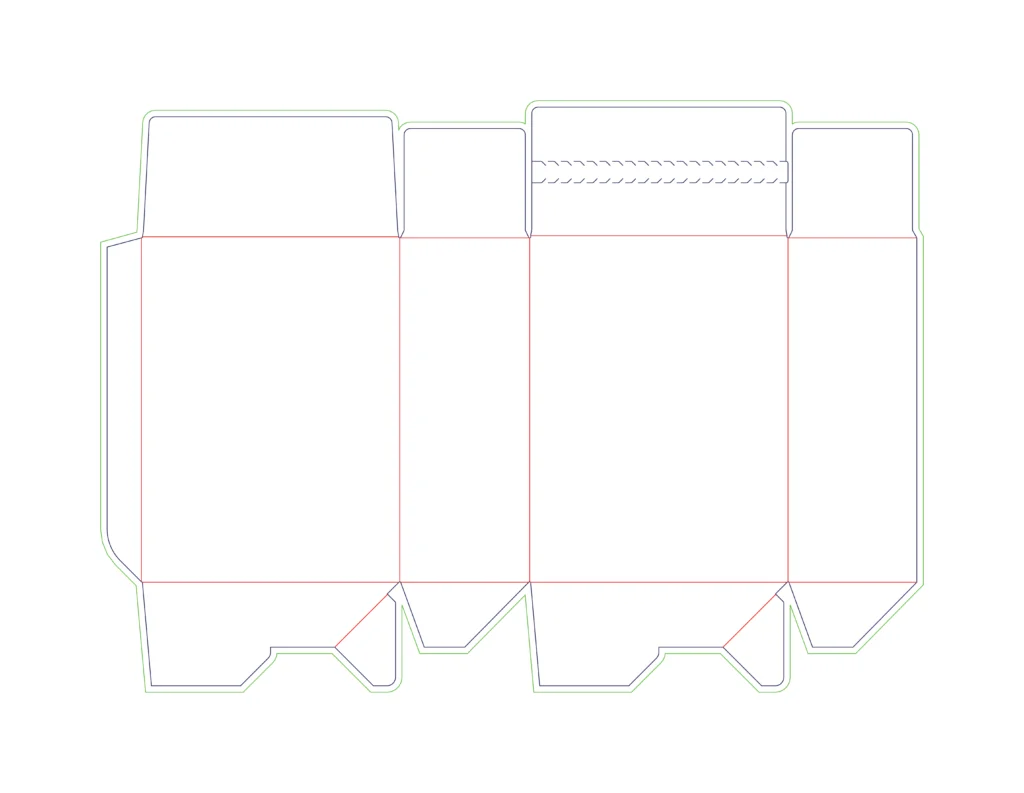

A tamper-proof design where ends are glued shut. Commonly used for food products, powders, and cleaning supplies.

Features ergonomic thumb cuts for easy opening. Frequently used for retail-ready packaging.

Combines a functional handle with sturdy paperboard for easy carrying. Ideal for food products like milk, juices, or baked goods.

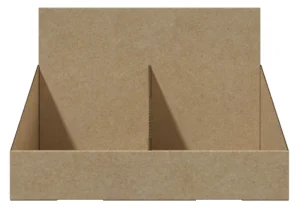

Feature an open design for product visibility and retail shelving. Often used for snacks, cosmetics, and promotional items.

A minimalist wrap-around style that works well for premium products. Common for perfumes, gift sets, and PR kits.

Merges the strength of auto-bottom designs with a secure tuck-top closure. Perfect for items needing frequent access.

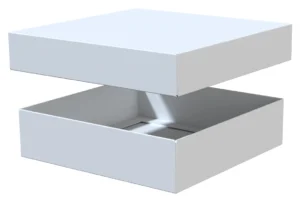

Offers a premium look with a separate lid and tray design. Frequently used for high-end products like jewelry or luxury cosmetics.

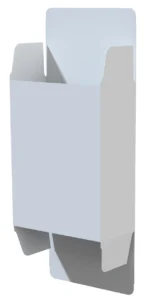

A holster box, also called a half box, is a special type of packaging. The top of the box stays completely open and has no closing tucks. Ideal for products like soap bars or other items where you want part of the product visible.

Includes a hanging tab, making it suitable for display on store racks. Popular for tools, small gadgets, and accessories.

Add internal support to hold multiple items securely. Seen in chocolate boxes, cosmetic sets, and tech accessories

Highlight products through unique shapes or transparent windows. Often used for premium or eco-friendly sustainable packaging.

Paperboard

Folding cartons are predominantly made from paperboard, a lightweight yet sturdy material that offers excellent printability.

Kraft Paperboard

For brands emphasizing sustainable packaging, kraft paperboard provides a natural, rustic appearance and is biodegradable.

People typically measure the thickness in points (pt), with one point equaling one-thousandth of an inch. The most common thicknesses for folding cartons are 16pt and 18pt. The packaging of the product and its weight determine the right thickness.

18pt

18pt paperboard is the standard thickness used for most products. It provides a good balance between strength and flexibility, making it ideal for a wide range of items.

For example, if you are packaging heavier items like glass jars for cannabis or cosmetics, 18pt is a good choice. It makes sure the box is strong but not too bulky. Similarly, for standard product packaging that requires a robust structure, 18pt is often the go-to choice.

16pt

For lightweight products such as mascara, small bottles of lotion, or creams, 16pt is often sufficient. These products tend to be tall and narrow, so they don’t require as much structural support as bulkier items. 16pt offers enough durability to protect the product while keeping the packaging lightweight and cost-effective.

The appearance of the material plays a crucial role in brand perception. For products that need a premium look, like cosmetics or luxury items, smooth, high-quality paperboard works well. It is often white or coated and gives an elegant, attractive finish. Custom printing, embossing, and foil stamping enhance the visual appeal of the packaging.

Consumers are increasingly concerned about sustainability. Choosing eco-friendly materials, such as recycled paperboard or kraft paper, can reduce the environmental impact of the packaging. Additionally, selecting materials that are recyclable or biodegradable aligns with green initiatives and appeals to environmentally conscious consumers.

Finalize both structural and graphic elements

High-quality printing on paperboard, followed by precise cutting into desired shapes

Automated machines fold and glue the cartons into flat-packed forms for easy shipping

Rigorous inspections to ensure the final product meets specifications

Folding cartons find applications across a wide variety of industries:

Snack boxes, cereal cartons, and takeout packaging

Medicine boxes with tamper-evident features

Stylish packaging for lipsticks, creams, and perfumes

Secure boxes for gadgets and small devices

Leading folding carton manufacturers and folding carton suppliers include:

These companies are renowned for innovative designs, sustainable packaging initiatives, and exceptional quality control.

Folding cartons are the cornerstone of cost-effective packaging solutions. Their versatility, wide range of styles, and eco-friendly features make them a preferred choice across industries. From straight tuck designs to specialty top and bottom closures, folding cartons meet diverse needs while supporting sustainable practices.

No, manufacturers make folding cartons from paperboard. They are lightweight and used for retail packaging. In contrast, manufacturers make corrugated boxes from fluted paperboard. They are stronger and used for shipping and storage.

Printers usually use offset printing to print folding cartons, transferring ink from plates to paperboard. This ensures high-quality images and designs for branding and product info.

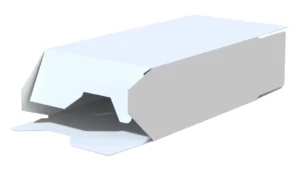

To fold a folding carton:

1.Unfold the flat box.

2.Fold along the creases.

3.Close the bottom (either tuck or lock).

4.Fold and secure the top flaps.

Folding cartons can last for 12 months or more if stored correctly. Keep them in a cool, dry place. Paperboard is strong, but it can break down when exposed to moisture or direct sunlight.

Paper cartons are generally better for sustainability, as they are biodegradable and recyclable. Plastic cartons, while durable, have a higher environmental impact and are less eco-friendly.